UCSD Fuel Cell Team Demonstrated Record Performance for Zirconia-Based Solid Oxide Fuel Cells

January 2019

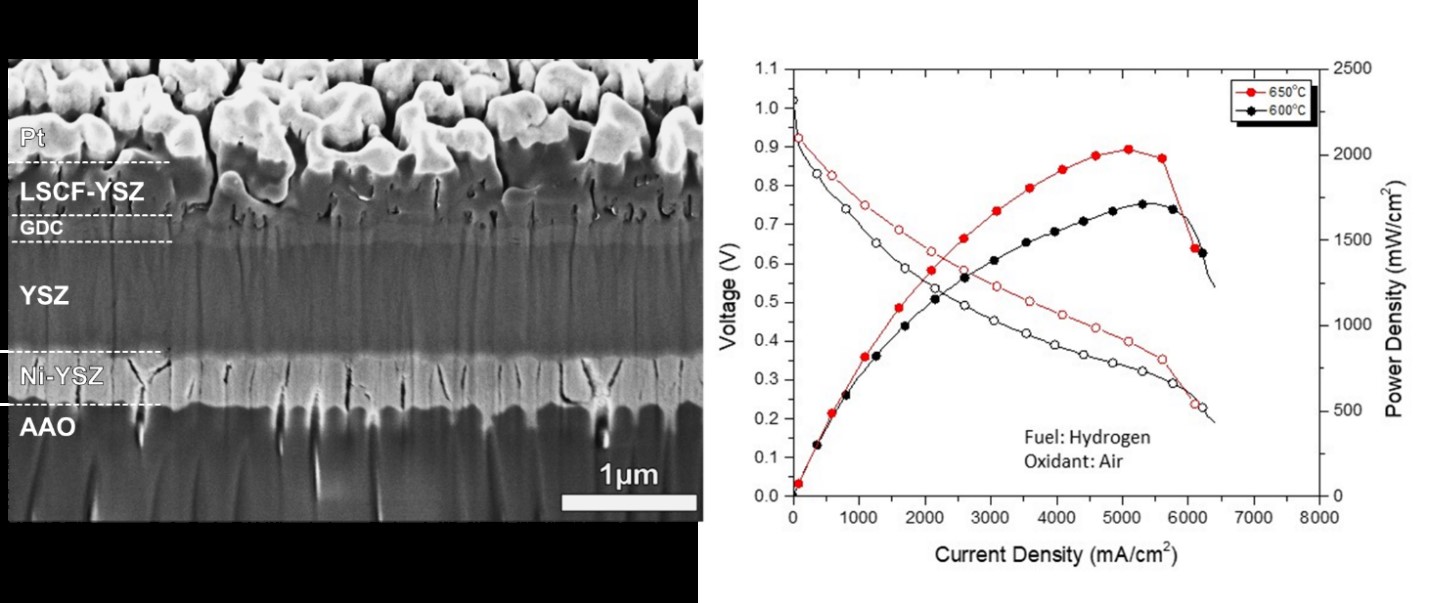

The UCSD Fuel Cell Team recently demonstrated the best cell performance for zirconia-based solid oxide fuel cells (SOFCs) at reduced temperatures (600oC-650oC vs. present operating temperatures of 750oC-800oC). Peak power densities of ~2 W/cm2 and 1.7 W/cm2 were achieved with hydrogen fuel at 650oC and 600oC, respectively. The SOFC exhibiting these extraordinary performances is a thin-film multilayer structure fabricated by a sputtering process developed by the team. The cell is based conventional configurations made of common SOFC materials: a fully dense yttria-stabilized zirconia (YSZ) electrolyte sandwiched between a porous lanthanum strontium cobalt iron (LSCF) perovskite-YSZ nanostructured cathode with a gadolinium doped ceria (GDC) interlayer, and a porous Ni-YSZ nanostructured anode. A scanning electron microscope (SEM) micrograph of the cell, cross-sectioned by focused ion beam (FIB), along with cell performance curves are shown below in the figure. The UCSD Fuel Cell Team consists of Principal Investigator Dr. Nguyen Minh, his Postdoctoral Scholar Dr. Yoon Ho Lee, and Visiting Scholar Dr. Tuyen Tran of UCSD/CER, Prof. Eric Fullerton and his graduate student Haowen Ren of UCSD/CMRR, and Prof. Shirley Meng and her graduate student Erik Wu of UCSD/NanoEngineering. This work is performed under the project “Innovative, Versatile and Cost-Effective Solid Oxide Fuel Cell Stack Concept” funded by the US Department of Energy/National Energy Technology Laboratory (DOE/NETL). The research on high-performance SOFCs at reduced operating temperatures is an element of the project to develop an efficient, reliable and cost-effective fuel cell technology for future commercialization.

The SOFC is an all-solid fuel cell known for its fuel flexibility. The main attractive feature of this type of fuel cell is its clean and efficient generation of electricity from a variety of fuels. Suitable fuels include hydrogen, natural gas, biogas, alcohol, gasoline, diesel, coal gas and other practical fuels. SOFCs are being considered for a broad spectrum of power generation applications, ranging from watt-size devices to multi-megawatt power plants, covering all market sectors (mobile/portable, transportation, stationary). SOFCs when operated in reverse (electrolysis) mode can also be used to produce hydrogen (from water) or oxygen (from carbon dioxide for example). Potential applications in this case include industrial production of hydrogen, hydrogen for energy storage and oxygen generation for space use.